Close

Close

Case Study

In practice, this has meant that British energy companies are now importing wood pellets from the softwood forests of the Southeast United States. For the purposes of carbon accounting, UK regulators consider burning biomass to be inherently carbon neutral, and they shower the sector with subsidies accordingly. However, the real climate benefits of this system are subject to many variables pertinent to the true climate impact from any specific biomass source.

Drax Group PLC is a British energy company that once relied heavily on coal (its power station in North Yorkshire was one of the largest coal fired plants in Europe) and is now shifting its focus towards renewable feedstocks. The company, which aims to be carbon negative by 2030, has already partially converted North Yorkshire to biomass, making it the largest single-site renewable power generator in the UK.

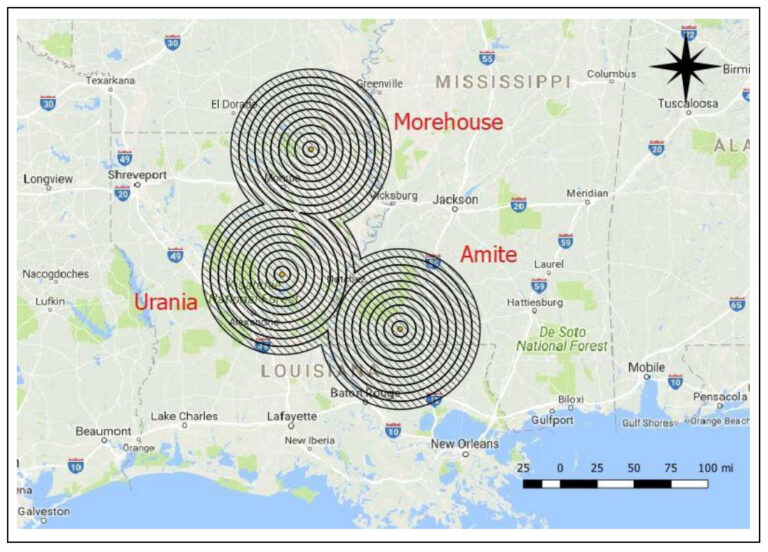

The southeast USA has become the leading source of biomass for UK power generation. Drax’s subsidiary, Drax Biomass, owns and operates three pellet mills in Mississippi and Louisiana that create fuel pellets from tree length logs mixed with sawmill residues.

But the impact of producing these pellets on the carbon stocks of the surrounding forests is unknown. In order to improve forest management, mitigate climate change, and develop good environmental protection legislation, the Southern Environmental Law Center (SELC) and the National Wildlife Federation (NWF) hired Spatial Informatics Group to conduct a Carbon Life Cycle Assessment (CLCA) on pellets from Drax’s facilities.

Accordingly, SIG’s scientists undertook this work in two phases. First, in collaboration with the Pinchot Institute for Conservation, we focused on improving our understanding of business-as-usual forest management in the region; we wanted to know what would have happened in those forests absent pellet mill demand for wood.

In the project’s second phase, SIG’s team of carbon modeling experts undertook a full CLCA for all three Drax pellet mills to construct mill-specific pellet carbon footprints. These CLCAs are based on forest growth and yield models extending 40 years from the start of the project.

We found that the three mills draw feedstock from seven million acres of nonindustrial private softwood plantations. For each mill and its specific mix of logs and sawmill residues, we calculated Carbon Parity Time – the time it takes for the energy source to prevent as much carbon dioxide from entering the atmosphere as was emitted during its production. This is the point at which a renewable technology begins to provide net environmental benefit.

Because our analysis compared the greenhouse gas implications of pellet production with the alternative of business-as-usual forest management in the region, and placed it in the context of near future generation systems available to UK power companies, we were able to provide a more complete picture that incorporated many more variables.

We found that pellets from these mills did not reach carbon parity within the 40 year modeling period. In other words, keeping the trees in the forest and managing as usual, rather than turning them into pellets and shipping them to the UK to be burned, had more greenhouse gas benefits.

SIG’s work called into question the supposed climate benefits of sourcing American pellets from additional forest harvests to produce electricity in the UK. It led to our partner SELC calling for an end to subsidies for biomass electricity generation in the UK and EU in favor of zero-emitting renewables like wind and solar power generation.